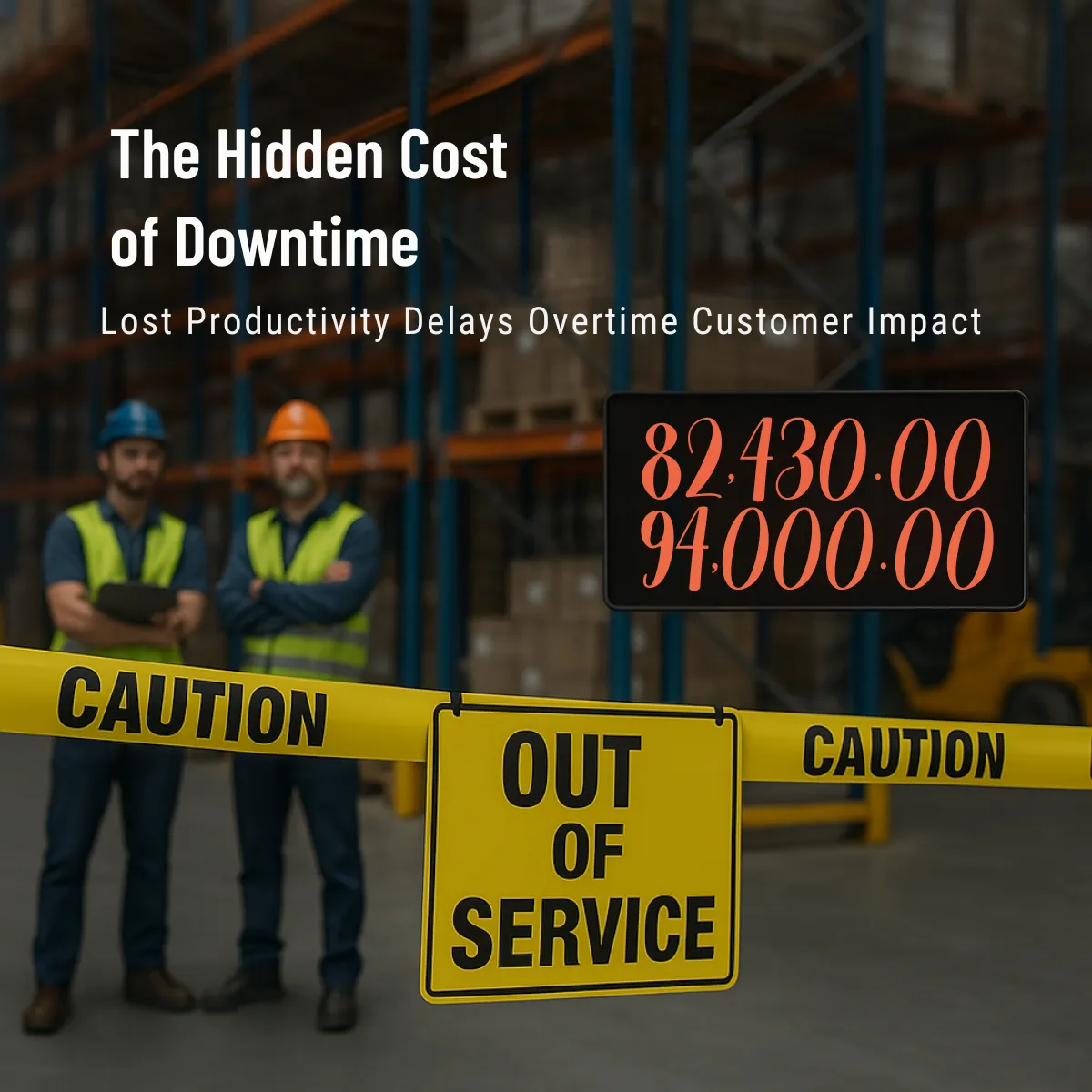

The Hidden Cost of Rack Downtime

When most people think about rack damage, they focus on the obvious:

✅ Repair costs

✅ Replacement parts

✅ Inspection fees

But there’s a much bigger, often invisible, price tag attached: Downtime.

Every minute your racks are out of commission, you’re not just dealing with repairs — you’re losing operational capacity. And that impacts much more than your maintenance budget.

Here’s where the hidden costs pile up:

🚧 Lost Productivity

Crews can’t access inventory. Orders get delayed. Teams get backed up.

🚧 Logistics Disruptions

Forklifts reroute. Inventory gets moved (and sometimes misplaced). Workflow efficiency takes a hit.

🚧 Increased Labor Costs

Overtime hours and extra shifts are often required to catch up once racks are back online.

🚧 Customer Satisfaction

Late shipments damage your reputation, erode customer trust, and may even cost you future business.

🚧 Safety Compromises

Temporary workarounds to avoid damaged areas can create new hazards, putting employees at risk.

Downtime isn’t just inconvenient. It’s expensive.

👉 That’s why proactive inspections aren’t a luxury they’re a strategic investment.

At Rusch Rack Inspections, we help you spot small issues before they create big disruptions. Preventative inspections keep your operation running safely, smoothly, and profitably.

Don't let hidden costs eat into your bottom line.

📞 Schedule your next rack inspection today.

Because every minute matters.